Technology for the Future

Dry Fiber Technology

Technology that transforms fibrous raw materials into something that has tangible value

Create materials with variable functions by defibrating, binding, and forming raw materials according to the application.

How Dry Fiber Technology works

Separates materials into fibers by mechanical force instead of using water1

Advantages of waterless defibration

Effectively separates various materials into fibers

Rapid defibration

Water-soluble materials can also be added

1 Moderate humidity is required.

How Dry Fiber Technology works

Advantages of waterless defibration

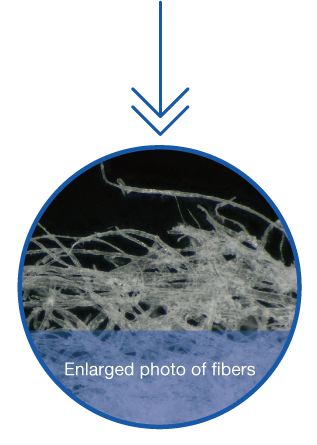

Feature 1Fiber loosening — Discover new functions through defibration

Loose fibers are

(1) dry and

(2) fiber length and shape can be controlled.

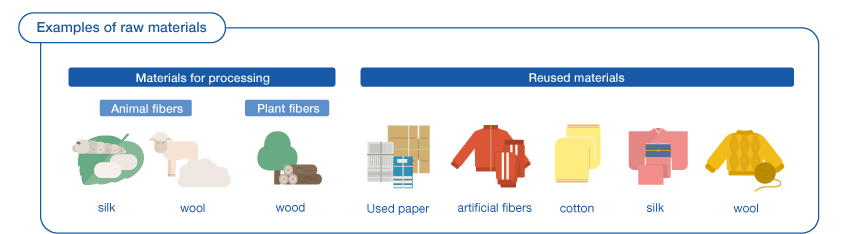

What kinds of things can be defibrated?

Various kinds of fibrous materials can be defibrated — animal, plant, and man-made.

Defibration

with Dry Fiber Technology

Fiber length and shape can be controlled

Short ↔ Long

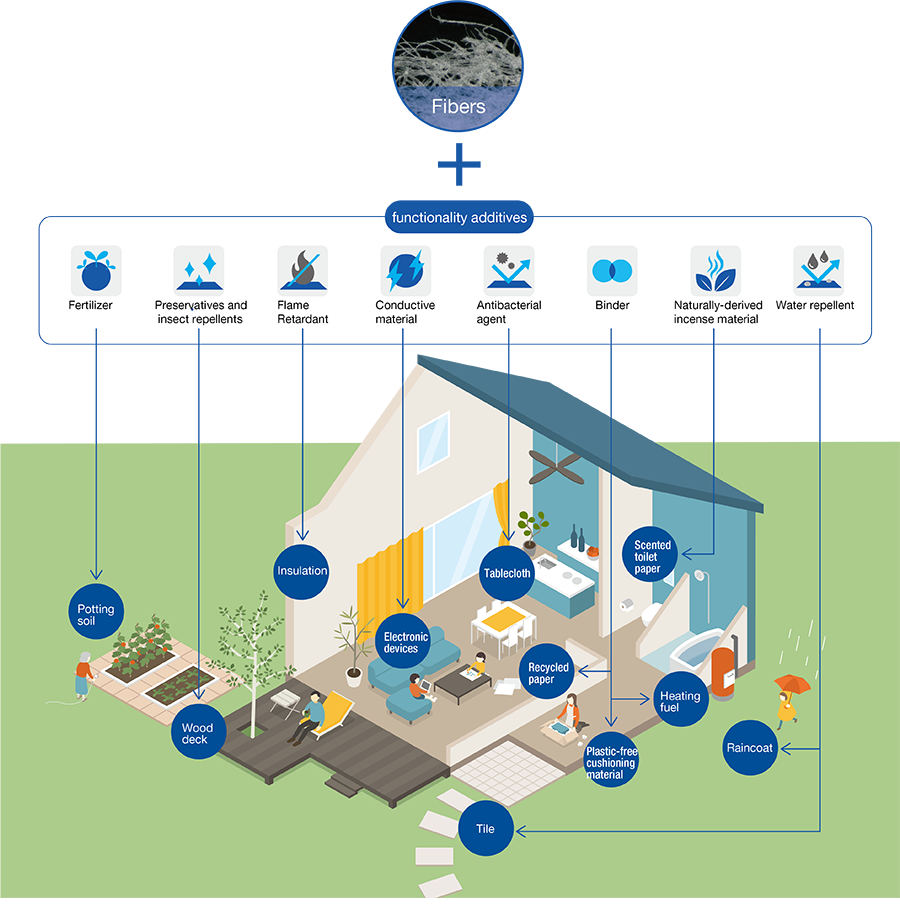

Feature 2Advanced functionality — Add functional materials to fibers to create raw materials with variable functions

You can endow raw materials with different characteristics by adding functional materials.

The ability to add them in a dry process means that not only do you have a much broader range of materials to choose from, but you can also control the concentration and location.

Feature 3Easy processing — Mold fibers into an easy-to-use shape

Defibrated raw material can be processed into shapes needed for a given manufacturing process or application.

Controllable density

You can control the density according to your application.

You can also vary and control the distribution of fibers.

Varying and controlling the distribution of fibers allows you to endow goods with different properties. For example, you could give an article a hard surface to give it strength.

Low density ↔ High density

Create different shapes depending on the forming or molding method

Fibers can be processed for use in press work, injection molding, and a variety of other manufacturing methods.

It can be used for paper products and plastic molded products that have variable functions.

Press forming

Injection molding

Whether you wish to make materials or commercial products with variable functions, we can help.